HOME Business Areas Processes

Processes

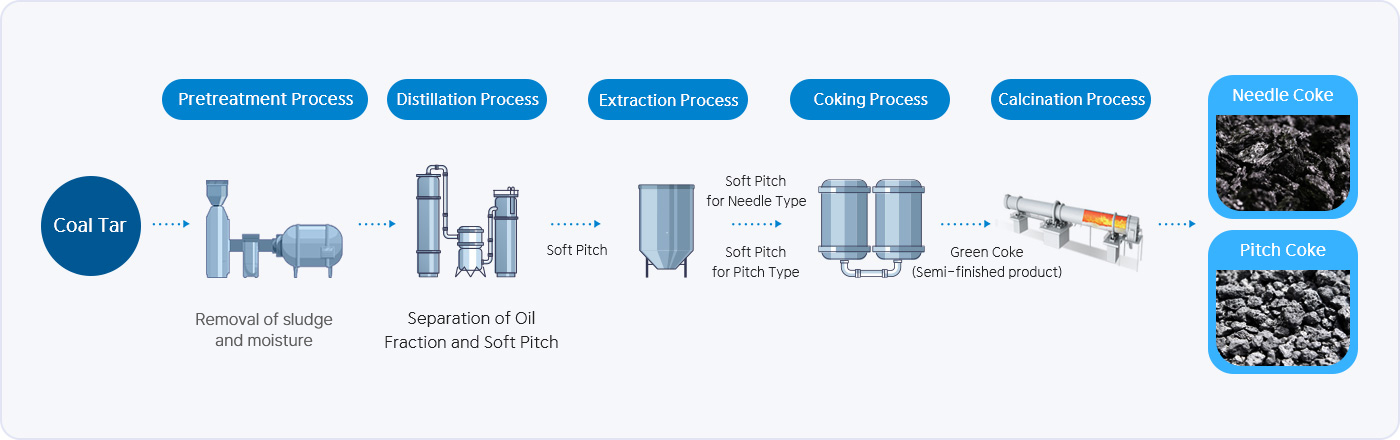

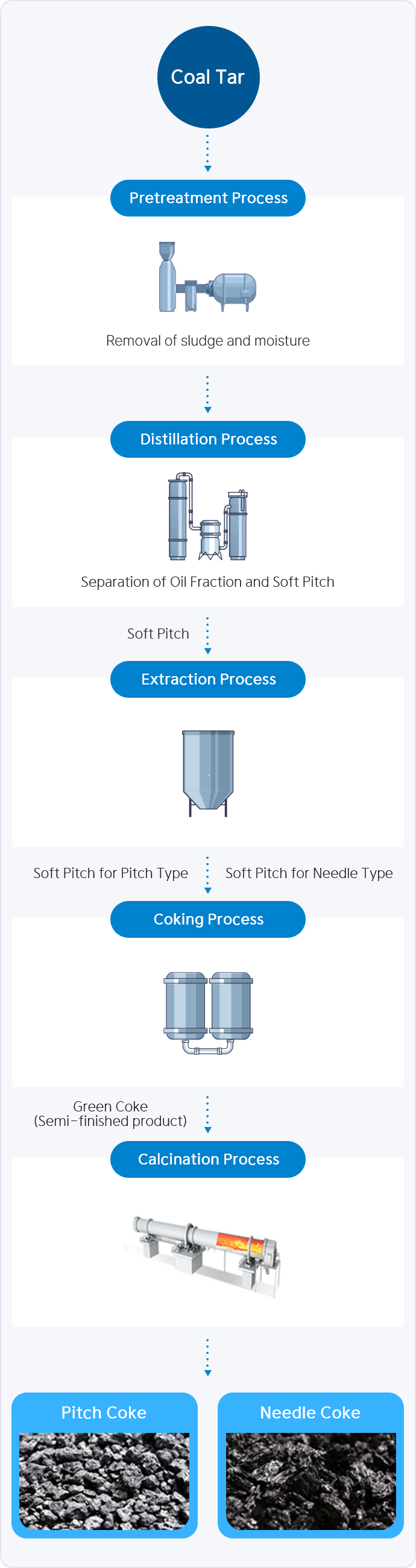

-

Pretreatment :Utilizing a centrifuge separator facility, we produce refined tar by removing moisture and sludge in Coltar.

-

Distillation Process :We heat Coal Tar, our raw material, separating it into Oil Fraction and Soft Pitch, leveraging the differences in their boiling points.

The resultant Oil Fraction includes Light Oil (BTX), Naphthalene Oil, Absorption Oil, and Creosote Oil. -

Extraction Process :This process involves the removal of elements from the Soft Pitch obtained from distillation, hindering anisotropy, and segregating it into soft pitch for needle and pitch.

The factor that disrupts anisotropy is used in soft pitch for pitch coke for an isotropic structure. -

Coking Process :Soft Pitch undergoes a Polycondensation reaction to generate semi-finished Green Coke for Needle and pitch applications.

Cracking Gas and Creosote Oil are by-products of Green Coke manufacture. -

Calcination Process :We employ a Rotary Kiln to enhance the crystallinity of the coke under high-temperature conditions, ultimately yielding Needle and Pitch Coke.

The high-temperature exhaust gas generated at this stage is cleaned using environmental equipment, recovering heat via a boiler and producing steam.